In today’s environmentally conscious and efficiency-driven world, businesses are constantly seeking opportunities to reduce costs, optimize production, and adopt sustainable practices. If you’re in the poultry, packaging, or recycling industries—or even exploring new ventures—an egg tray machine could be one of the smartest investments you’ll ever make.

This blog explores why an egg tray machine is a worthy investment, detailing the financial, operational, and environmental benefits it brings to your business, whether you’re a poultry farm, a waste paper recycler, or an entrepreneur targeting eco-packaging.

🥚 What Is an Egg Tray Machine?

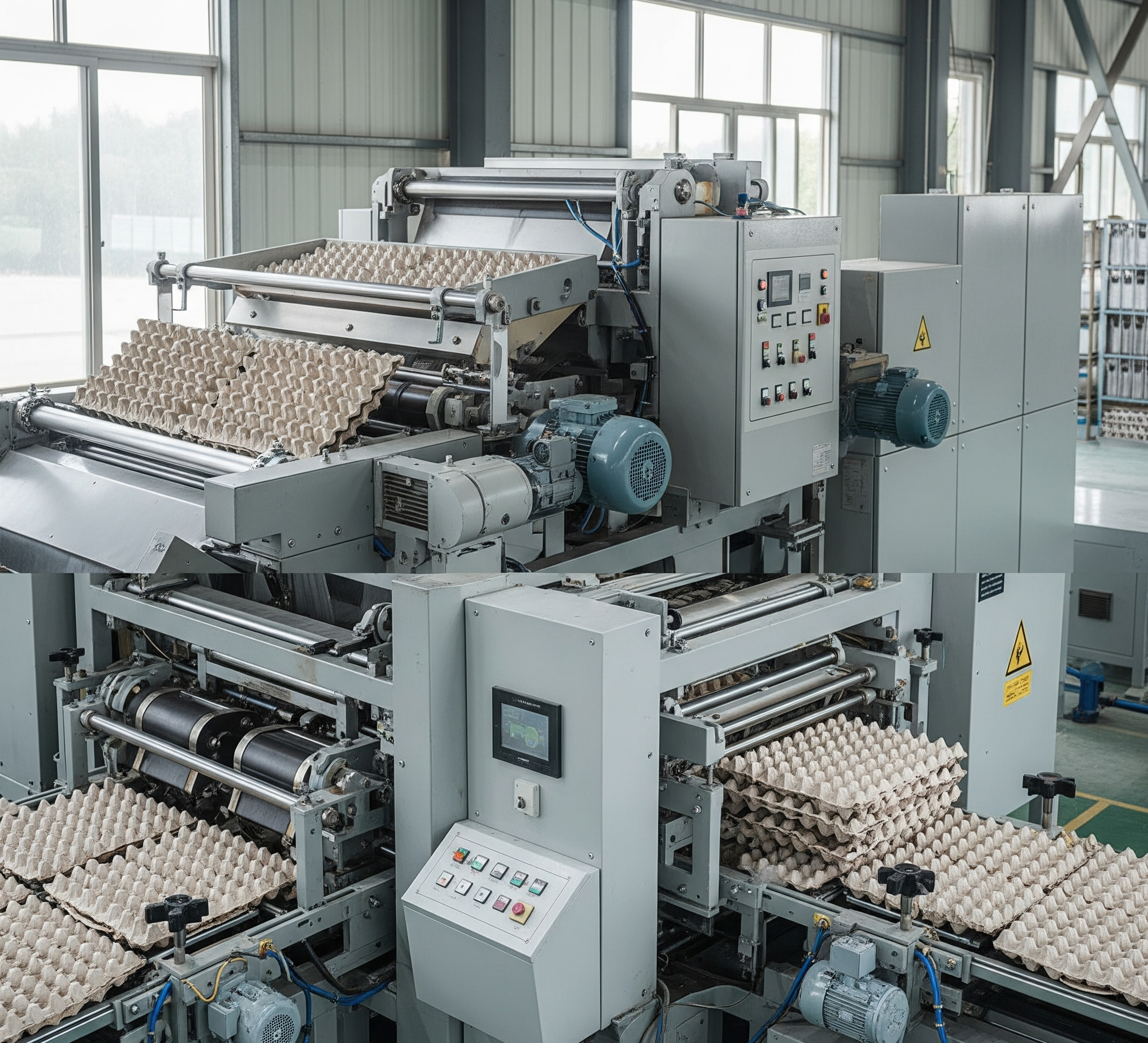

An egg tray machine, also known as an egg tray production line, is a device that uses waste paper or pulp to create molded trays used for storing and transporting eggs. These machines can produce:

- 6-cell, 12-cell, 24-cell, or 30-cell trays

- Fruit trays

- Shoe trays

- Industrial packaging

The system typically includes:

- Pulping unit (for processing raw materials like waste paper)

- Molding system (for shaping the trays)

- Drying line (sun, brick, metal, or automated drying)

- Packing section (for bundling the finished trays)

🧠 Why Is It a Smart Business Move in 2025?

The demand for eco-friendly packaging has never been higher. The global shift away from plastics, the rise in poultry consumption, and increased emphasis on recyclable, biodegradable solutions are driving growth in this industry.

According to market reports:

- The global molded fiber packaging market is expected to reach USD 13.5 billion by 2027

- Egg consumption in India alone crossed 100 billion eggs per year and continues to rise

- The Indian government is actively supporting MSMEs investing in waste-to-wealth technologies

Clearly, now is the perfect time to get involved.

💰 1. Cost-Effective Production = High ROI

One of the most convincing reasons to invest in an egg tray machine is the low-cost input and high-profit output.

Low Input Costs:

- Raw materials like waste paper, used cardboard, newspapers, or corrugated boxes are inexpensive and widely available

- Minimal labor requirement with semi-automatic or fully-automatic machines

- Energy-efficient models reduce utility bills

High Output Value:

- Egg trays are in constant demand

- Profitable resale to poultry farms, egg distributors, grocery chains, and exporters

- Packaging demand for other produce or electronics also adds revenue streams

ROI Example:

A small-scale egg tray machine producing 1000 trays/hour can cover its cost in 4–6 months, depending on local demand.

♻️ 2. Sustainable and Eco-Friendly

With rising awareness about sustainability, governments, industries, and even consumers are shifting toward green alternatives. Pulp egg trays offer:

- 100% biodegradability

- Compostability after use

- Safe recycling process

Egg tray machines help your business:

- Convert waste paper into wealth

- Reduce carbon footprint

- Support circular economy models

If your business emphasizes sustainability, this machine fits perfectly with green branding and ESG (Environmental, Social, Governance) initiatives.

🛠️ 3. Versatility and Scalability

Egg tray machines are not limited to just eggs. They can produce trays for:

- Fruits (apple trays, tomato trays)

- Cups and seedling pots

- Shoe supports

- Glass bottle trays

- Electronics packaging

Machine Types:

| Machine Type | Capacity | Ideal For |

|---|---|---|

| Manual | 800-1200 trays/hour | Small startups |

| Semi-Automatic | 1500–3000 trays/hour | Medium-scale businesses |

| Fully Automatic | 4000–9000 trays/hour | Large factories/exporters |

Scalability: Start small, then expand by adding drying lines, automation, or higher molds. It’s easy to scale with demand.

🔧 4. Low Maintenance and Long-Term Use

Most modern egg tray machines are designed for long service life. With proper upkeep, these machines can run smoothly for years.

Advantages:

- Made from corrosion-resistant materials

- Fewer moving parts = less breakdown risk

- Easily available spare parts

- User-friendly control systems

Pro Tip: Choose a model with automatic cleaning and mold-changing features to reduce downtime and increase production efficiency.

🌐 5. Expanding Global and Local Markets

Egg trays are a global commodity. From India to Africa to the Middle East, the demand continues to surge, driven by:

- Growth of poultry industry

- Increase in egg exports and domestic transport

- Government food security programs

- Local kirana shops, mandis, and supermarkets needing safe packaging

Exporting egg trays or setting up franchise supply models locally can multiply your business avenues.

🏭 6. Great for Poultry Farms and Egg Suppliers

If you already operate a poultry farm, investing in an egg tray machine means:

- No more buying trays from third-party vendors

- Complete control over tray quality and design

- Better protection for eggs during transport

- Lower operational costs over time

This not only saves money but also improves your farm’s branding and packaging consistency.

👷 7. Government Support and Subsidies in India

The Indian government, under schemes like MSME Udyam Registration, Startup India, and PMEGP, supports machinery purchases that convert waste into value.

You can avail:

- Bank loans for equipment setup

- Subsidies for eco-machinery

- Tax benefits on recycled product manufacturing

States like Tamil Nadu, Andhra Pradesh, and Maharashtra offer additional poultry and recycling sector incentives.

📦 8. Endless Business Opportunities

Here are business models made possible by owning an egg tray machine:

- Tray Manufacturer & Wholesaler – Sell to farms, stores, packaging dealers.

- Poultry Integration – Supply eggs and trays under your brand.

- Waste Paper Buyer – Collect waste paper, recycle it into trays.

- Export Business – Send trays to poultry-dense countries.

- Custom Tray Maker – Serve niche markets like fruit, shoes, gadgets, etc.

With a little marketing, your investment can turn into a full-scale manufacturing brand.

📈 Real Case Study

Veena Egg Tray Services, India

Started with a semi-automatic egg tray machine in Hyderabad using local waste paper. Today, they:

- Sell over 2 lakh trays per month

- Supply to poultry farms across South India

- Buy old newspapers from local buyers

- Have diversified into custom molded packaging

Their success proves that recycled paper + egg tray machine = long-term business sustainability.

🤖 Future Trends: Smart Egg Tray Machines

In 2025 and beyond, machines are becoming smarter:

- IoT-enabled tray machines track production in real-time

- AI mold monitoring ensures perfect tray shape

- Solar drying systems for off-grid operations

- Fully automatic packaging lines

Investing now prepares you for these innovations—keeping your business future-ready.

💬 Final Thoughts: A Small Investment, Big Payoff

Buying an egg tray machine may seem like a manufacturing leap—but with growing demand, easy input sourcing, and multiple revenue channels, it’s a low-risk, high-return decision.

Whether you’re:

- A poultry farmer looking to save on packaging

- A recycler turning waste into gold

- An entrepreneur wanting to tap into the eco-friendly packaging sector

👉 An egg tray machine is a truly worthy investment that pays off across profitability, sustainability, and scalability.