We’ve all seen them, those familiar, unassuming cartons cradling our breakfast essentials. But the humble egg tray is far more than just a protective shell. In the world of packaging, it represents a fascinating intersection of material science, engineering, and increasingly, sustainability. At Veena Egg Tray, we’re not just making egg trays; we’re innovating for a more efficient and environmentally responsible future. Our focus is on bringing you the best in egg packaging solutions.

The Material Revolution: Beyond Virgin Pulp

For decades, recycled paper pulp has been the backbone of egg tray manufacturing. While highly sustainable in its own right, advancements are pushing the boundaries:

- Agricultural Waste Integration: Imagine egg trays made from rice husks, wheat straw, or bagasse (sugarcane waste)! These agricultural byproducts, often discarded or burned, are being valorized into viable fiber sources. This not only reduces reliance on virgin timber but also creates new income streams for farmers and mitigates waste disposal issues.

- Biodegradable Polymers & Bioplastics: While still in nascent stages for mass-produced trays due to cost and scalability, research into incorporating biodegradable polymers or coatings derived from renewable resources is ongoing. This could lead to trays with enhanced water resistance or even trays that decompose more rapidly in specific conditions.

- Nanocellulose Enhancements: Cutting-edge research explores the use of nanocellulose – tiny cellulose fibers with exceptional strength – to potentially improve the structural integrity and even reduce the material weight of pulp egg trays, leading to further resource efficiency.

Precision Engineering: Design for Durability & Protection

The corrugated peaks and valleys of an egg tray are not arbitrary. They are the result of meticulous engineering designed to:

- Optimize Impact Absorption: The unique geometry is a carefully calculated system for distributing impact forces, preventing shell cracks during transport and handling. This is crucial for maintaining egg quality from farm to table. To understand more about the journey of eggs and their protection, learn more about proper handling of eggs from hen to consumption to ensure safety.

- Control Humidity and Airflow: The porous nature of molded paper pulp packaging allows for some breathability, which can be crucial for extending the shelf life of eggs by managing humidity levels around them. Advanced designs may even incorporate micro-perforations for enhanced ventilation.

- Stacking Efficiency: The interlocking design of modern egg trays allows for stable, high-density stacking, maximizing space utilization during storage and transit, and reducing logistical costs. This isn’t just about fitting more in a truck; it’s about minimizing the carbon footprint of egg production.

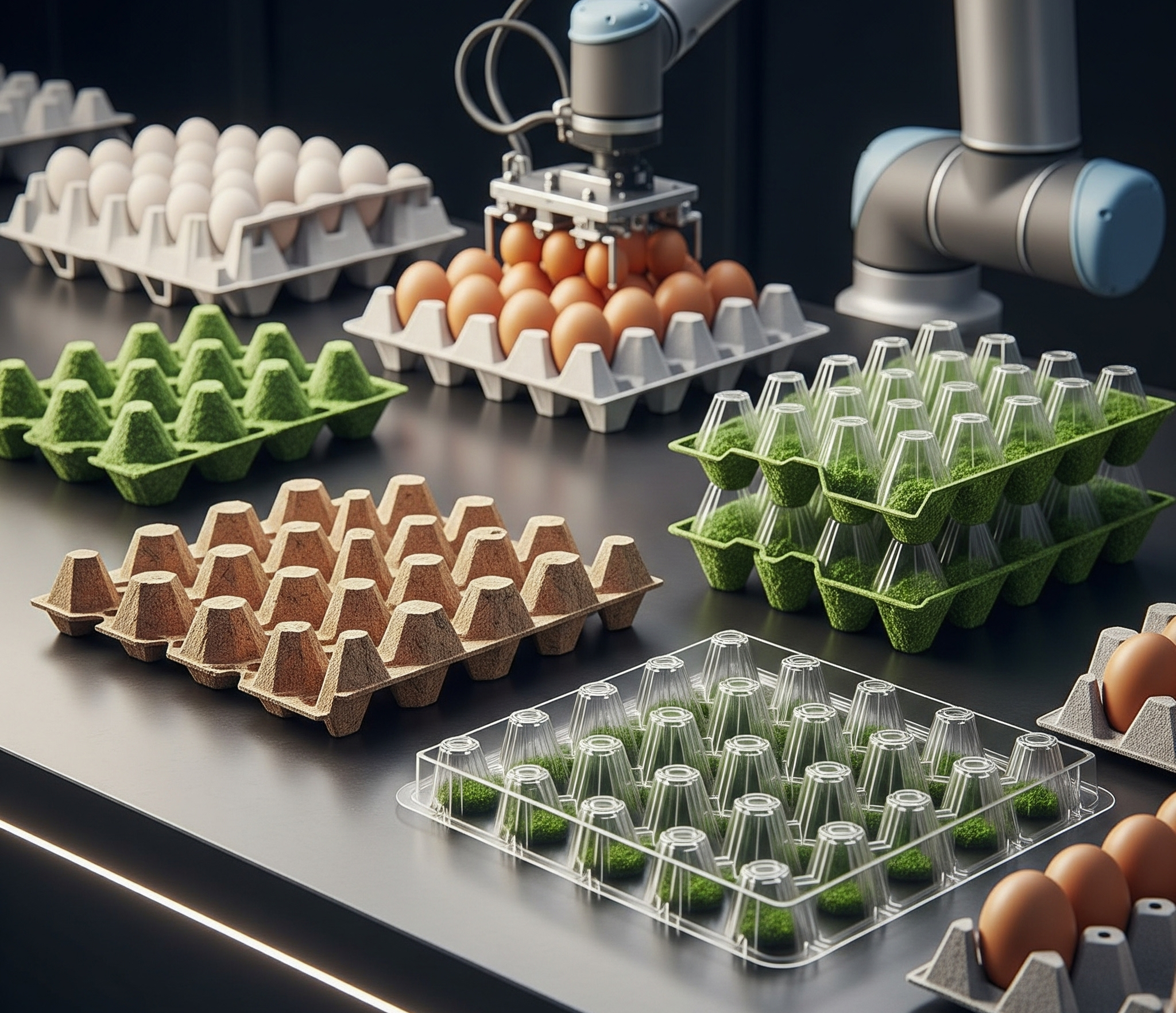

The Manufacturing Marvel: Efficiency & Automation

Modern egg tray production facilities are marvels of automation and resource efficiency:

- Closed-Loop Water Systems: Water is a critical component in pulp molding. Advanced facilities employ sophisticated filtration and recirculation systems, significantly reducing water consumption and minimizing wastewater discharge.

- Energy Optimization: From efficient pulping processes to optimized drying ovens, manufacturers are constantly seeking ways to reduce energy consumption. This includes leveraging waste heat recovery systems and exploring renewable energy sources to power their operations. Dive deeper into the key considerations in the paper pulp manufacturing process that contribute to these efficiencies.

- Robotics and AI in Quality Control: Automated vision systems and robotics are being integrated into production lines for precise quality control, identifying defects with greater accuracy and speed than manual inspection. AI algorithms can even predict potential issues based on production data, allowing for proactive adjustments.

The Future is Sustainable & Smart

At Veena Egg Tray, we believe the future of egg trays is intertwined with sustainability and smart technology:

- Traceability and IoT Integration: Imagine “smart egg trays” with embedded QR codes or RFID tags that provide information on the eggs’ origin, packing date, and even temperature history during transit. This could revolutionize supply chain transparency and food safety. For broader insights into smart packaging trends, you can refer to reputable industry resources like Packaging Digest.

- Composability & Circular Economy: Our focus remains on creating trays that are not just recyclable but also readily compostable, seamlessly integrating back into the natural nutrient cycle. We are actively exploring partnerships to promote robust industrial composting infrastructure.

- Consumer Education: Part of our mission is to educate consumers on the proper disposal and recycling of egg trays, empowering them to participate in the circular economy.

The next time you reach for an egg, take a moment to appreciate the unsung hero that protects it. The egg tray, far from being a simple carton, is a testament to ongoing innovation in material science, engineering, and sustainable manufacturing. At Veena Egg Tray, we’re proud to be at the forefront of this evolution, delivering not just protection, but a promise of a more sustainable future.

What advanced features would you like to see in your next egg tray? Share your thoughts in the comments below!