When people hear paper pulp trays, the first thing that comes to mind is egg packaging. However, in today’s eco-conscious world, molded fiber and paper pulp trays have evolved far beyond that single use. With sustainability becoming a priority across industries, businesses are adopting eco-friendly, biodegradable, and recyclable packaging solutions to reduce plastic waste and improve brand value.

In this blog, we explore 7 creative and practical uses of paper pulp trays across different industries, highlighting why they are becoming a preferred packaging choice.

1. Food & Beverage Industry

Beyond eggs, paper pulp trays are widely used for:

- Fresh fruits like apples, pears, and avocados

- Bakery items and takeaway food

- Beverage cup holders

- Ready-to-eat meal packaging

Why it works:

Paper pulp trays provide excellent shock absorption, moisture resistance, and ventilation. They protect delicate food items while being compostable and food-safe. Restaurants and food brands prefer them as an alternative to plastic containers.

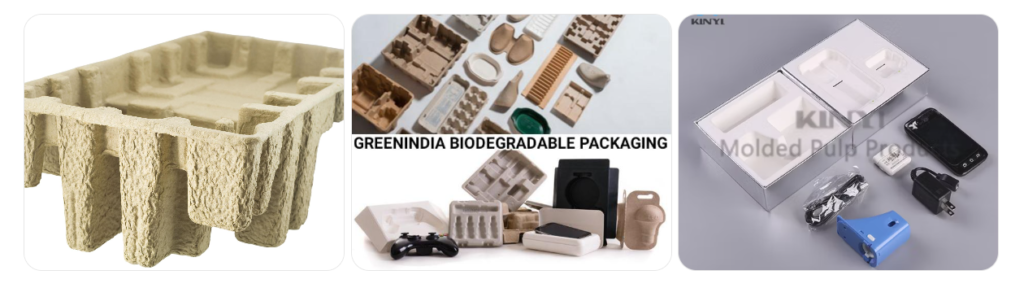

2. Electronics & Consumer Goods

Electronics brands are increasingly using molded pulp trays for:

- Mobile phones and accessories

- Headphones and small gadgets

- Remote controls and adapters

- Cosmetic electronic tools

Why it works:

Paper pulp trays are lightweight yet durable, offering excellent cushioning during shipping. They reduce plastic usage while ensuring product safety.

3. Agriculture & Horticulture

Farmers and nurseries use paper pulp trays for:

- Seed germination

- Plant nursery trays

- Organic farming

- Temporary plant pots

Why it works:

These trays are biodegradable and can be planted directly into the soil. They decompose naturally, enriching the soil and reducing transplant shock.

4. Medical & Healthcare Sector

In hospitals and clinics, paper pulp trays are used for:

- Disposable kidney trays

- Instrument packaging

- Medicine transport trays

- Laboratory sample holders

Why it works:

They are hygienic, disposable, and cost-effective. Since they are biodegradable, they reduce medical plastic waste significantly.

5. Cosmetics & Personal Care Industry

Sustainable beauty brands are turning to paper pulp trays for:

- Skincare kits

- Perfume packaging

- Gift boxes

- Makeup tool holders

Why it works:

Eco-conscious consumers prefer brands that use recyclable and plastic-free packaging. Paper pulp trays enhance brand image while maintaining product protection.

6. Automotive & Industrial Parts

In manufacturing and automotive industries, pulp trays are used for:

- Small engine components

- Precision parts

- Spare parts packaging

- Tool kits

Why it works:

They offer custom-molded protection, reducing movement and damage during transport. They are cost-effective compared to foam inserts.

7. E-commerce & Retail Packaging

With the rapid growth of online shopping, paper pulp trays are ideal for:

- Fragile product shipping

- Subscription boxes

- Gift hampers

- Sustainable retail packaging

Why it works:

They reduce breakage, are lightweight for shipping, and align with eco-friendly branding strategies.

Why Industries Are Switching to Paper Pulp Trays

Here are the key benefits driving adoption across sectors:

- ✅ 100% biodegradable and recyclable

- ✅ Made from recycled paper materials

- ✅ Cost-effective alternative to plastic

- ✅ Customizable shapes and sizes

- ✅ Excellent shock absorption

- ✅ Environmentally responsible branding

As governments and consumers demand sustainable packaging solutions, molded fiber trays are becoming a smart long-term investment for businesses.

Final Thoughts

Paper pulp trays are no longer limited to egg cartons. From electronics and agriculture to healthcare and e-commerce, their versatility makes them a powerful solution for modern industries.

If your business is looking to reduce plastic dependency and adopt sustainable packaging, paper pulp trays offer an innovative, cost-effective, and eco-friendly alternative.